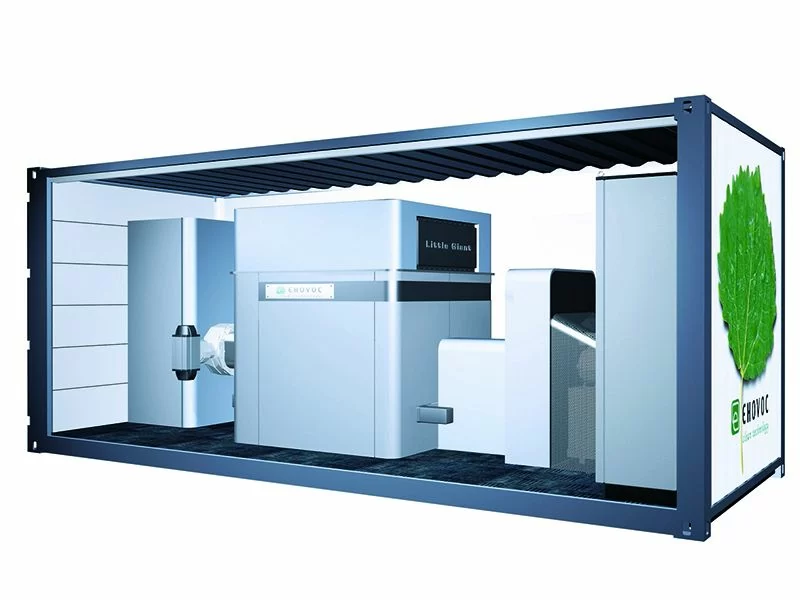

FFPC went all out and took the industry's leaders to install two sets of high-efficiency gas waste processing equipment. First, RCO (Regenerative Catalyst Oxidizer) was introduced by EHOVOC, a Finland company. Then there's RTO (Regenerative Thermal Oxidizer). RCO and RTO were primarily used to decompose the VOCs, ensuring that the exhaust emissions would not be discharged into our nature, which was in line with government regulations. Moreover, FFPC installed another new RTO equipment in 2023, meeting the current expansion of our capacity.

In addition to the hardware part, FFPC also places an environmental safety technical team with 6 personnel to maintain the routine operation of the above equipment. Other than that, the team also undertakes missions such as monitoring our waste gas and waste water. Regarding enterprise management, law compliance, ecological protection, and social responsibility are FFPC's greatest promises.

The primary function of these two sets of RTO equipment is to efficiently process the gas waste of organic solvents, which not only pass the government inspection for waste discharge but also protect the ecology and the earth, as these are the core value of FFPC.