Can't find the packaging material you need?

More Details on Packaging Solutions

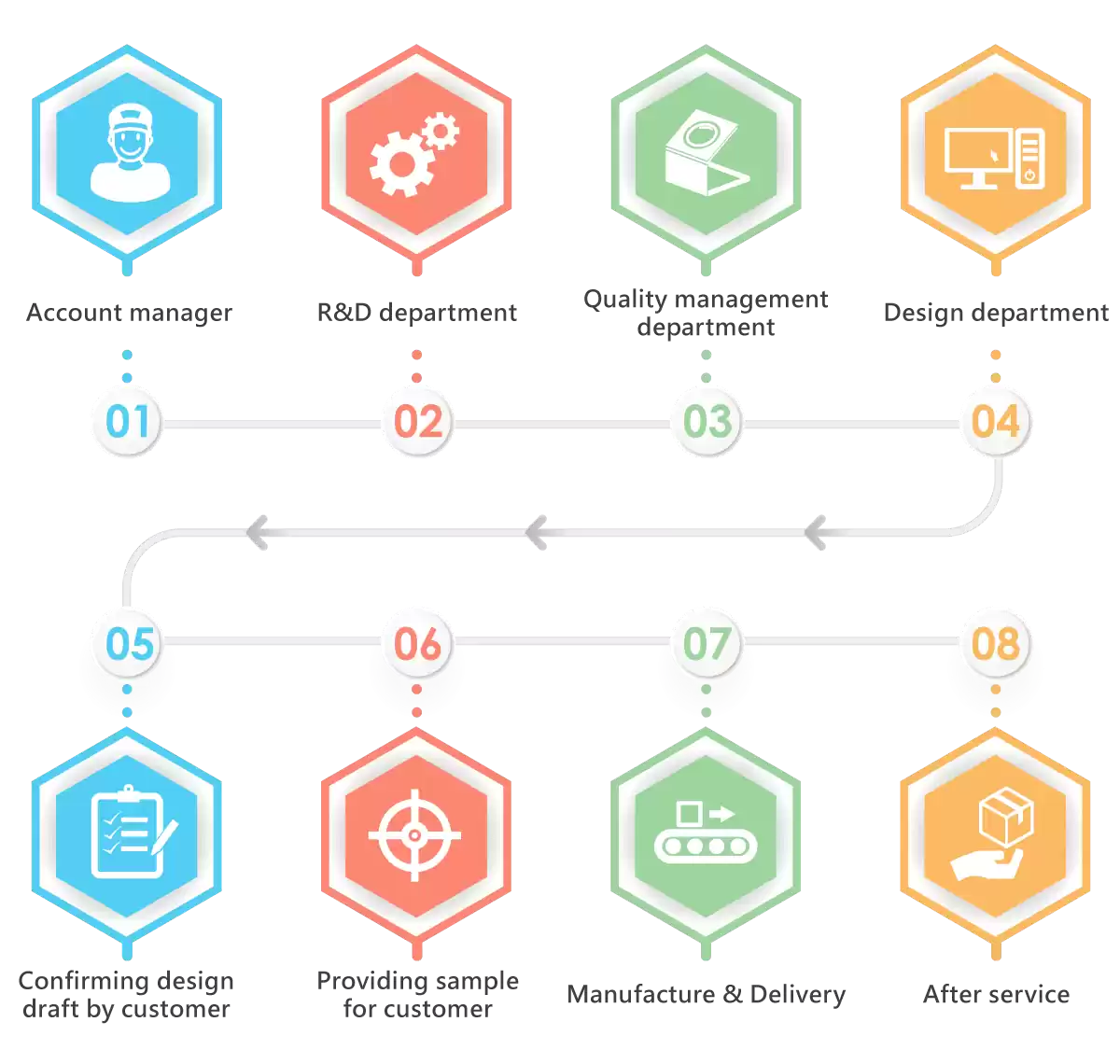

Our versatile packages serve various industries; contact us for details.

Contact us

Anti-static Coating (ESD-A) / Polyester Film (PET) // Aluminum Foil (AL) // Nylon Film (NY or PA) // Low-Density Polyethylene Film (LDPE or LLDPE) / Anti-static Coating (ESD-B)