SSB Product introduction

Also known as "ESD shielding bag" or "Mylar metallized bag/electroplated bag," the composite structure can also include nylon film (NY or PA).

Application

- Wafer box (wafer cassette)

- Tray

- Tape & reel

- Reticle box

- Printed circuit board (PCB), IC carrier

- IC packaging

- Electrostatic-sensitive electronic components

- Lenses

- Passive components (MLCC)

- Consumer electronics (motherboard, RAM)

Function

- Surface resistivity:10⁸~10¹¹ Ω

- Heat-sealable

- Vacuum-sealable

- Semi-transparent (contents can be identified)

- The color of the metallized layer affects barcode scanning recognition of packaged contents. (This can be improved by affixing labels to the package)

- Customizable printing of patterns and text

- "Surface printing" available: printed patterns and text are easy to identify; however, external forces may scratch and remove them

- "Inner printing" available: printed patterns and text will not fall off; however, the metallized layer may reduce the clarity of patterns and text

- Compliant with EU RoHS (Restriction of Hazardous Substances) and REACH SVHC (Substances of Very High Concern) regulations

- Compliant with Japan SONY SS00259 standard

- Compliant with California Proposition 65

- Discharge Shielding: <20nJ

- Static Decay: <2s

- Standard thickness: 110µ for anti-static nylon metallized bags, 95µ for anti-static metallized bags. (Other thicknesses can be customized)

- Production facility cleanliness: Class 10,000 cleanroom

Anti-static (nylon-included) electroplated bag/metallized bag structure:

Anti-static coating (ESD-A)/polyester film (PET)/aluminum metallization or vapor-deposited aluminum (ML, VM)//nylon film (NY or PA)//low-density polyethylene film (LDPE or LLDPE)/anti-static coating (ESD-B)

Anti-static electroplated bag/metallized bag structure:

Anti-static coating (ESD-A)/polyester film (PET)/aluminum metallization or vapor-deposited aluminum (ML, VM)//low-density polyethylene film (LDPE or LLDPE)/anti-static coating (ESD-B)

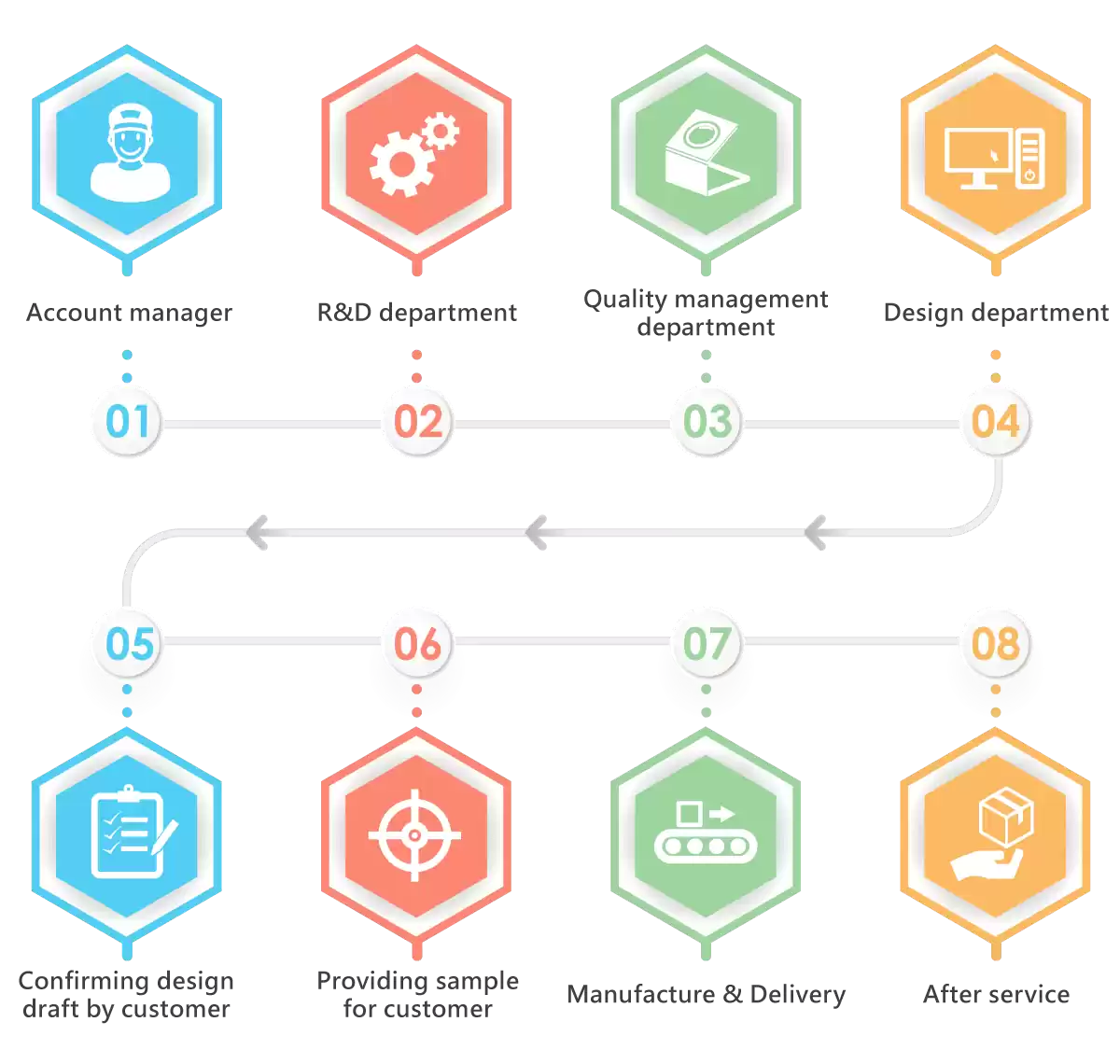

ODM& Manufacturing process

![SSB(Static Shielding Bag)/ Anti-static Metalized Bag SSB(Static Shielding Bag)/ Anti-static Metalized Bag]()

![SSB(Static Shielding Bag)/ Anti-static Metalized Bag SSB(Static Shielding Bag)/ Anti-static Metalized Bag]()